Homogenization of Fiber Composite Material Properties: An Adaptive Multiphysics Implementation

Fiber-reinforced composite materials are widely used for building lightweight parts in several application fields like aviation or naval industry. Here the longitudinal fibers, which take the main mechanical loads of the component, are embedded in a shape giving resinous matrix. The single constituents have fundamental different material properties, which are anisotropic and changing during the manufacturing processes influenced by various parameters like temperature, pressure or curing degree of the resin. For process modeling and design of manufacturing processes for larger scaled parts, in many cases the fibers matrix compound is not implemented in detail to save computational costs. Rather a macroscopic approach is used in most industrial applicable simulation models. Here the part is implemented as a porous medium with homogenized material properties, which are the results of the individual properties of the single components.

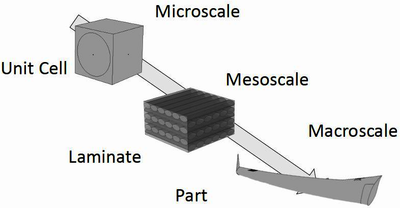

For determination of those homogenized properties, a unit cell containing fibers and matrix as well as additional components like stitching yarns e.g. can be used for considering behavior of the composite in detail. Aim is the homogenization of the material properties in the unit cell for application to larger models.

Various material properties e.g. in the fields of solid mechanics and heat transfer can be determined by using a unit cell model for homogenization of fiber-reinforced composites. Here a multiphysics approach shall be used for fast and reliable assessment of the parameters. In addition, the geometry and arrangement of the fiber tows can vary widely. Therefore, a manageable implementation and parametrical adaption is essential. Because of anisotropy of the parameters, combination of two-dimensional and three-dimensional models is needed.

In this paper COMSOL Multiphysics® is used for setting up an adaptive model for calculation of homogenized material properties of fiber reinforced composite materials. The multiphyiscs engine is used for determination of thermo-mechanical properties. Through the flexibility of the model an evolution from the idealized geometry to a more realistically unit cell with the implementation of various geometrical and physical influences is possible. So COMSOL Multiphysics® can be used to generate a wide range of homogenized material properties of fibre-reinforced composites with different starting materials and diverse material structures.

下载

- stolz_poster.pdf - 0.68MB

- stolz_paper.pdf - 0.61MB

- stolz_abstract.pdf - 0.13MB