Electrostatic Zipping Actuation of a Three-Chamber Peristaltic Micropump

While electrostatic actuators feature prominently among the most widely employed classes of actuators for microelectromechanical systems (MEMS), conventional embodiments of these devices (e.g., parallel plate structures) notoriously suffer from several significant drawbacks. Most consequential among these are the need for high actuation voltages, the weak force at large separation distances resulting from the inverse-square force law, and the limited possible range of motion that follows. To overcome these weaknesses, electrostatically actuated “zipping” structures have been introduced in which actuation is first achieved locally at a location with a small gap, allowing the remaining structure to “zip” closed as it is subsequently brought closer to the oppositely charged conductor. Channels and chambers with curved or gently sloped sidewalls, for example, have been demonstrated to enable such zipping motion of suspended diaphragms. By exploiting this gradual zipping effect, high-force actuation can be initiated at much lower voltages and a significantly larger range of motion can be achieved.

In this work, we numerically demonstrate the implementation of electrostatic zipping within a microfluidic device and systematically investigate how actuation is influenced by geometrical parameters such as microchannel (or chamber) aspect ratio, sloped sidewall angle, and corner curvature at the location where initial pull-in of the elastomer diaphragm occurs. Furthermore, we exhibit the application of this technique to the actuation of a valveless three-chamber peristaltic micropump. The architecture of the hypothetical micropump is such that no electric field is passed directly through the pumped fluid, enabling the manipulation of sensitive biofluids and other aqueous samples in potential applications ranging from on-chip bioanalysis to wearables-based therapeutic delivery. Moreover, due to the large range of motion made possible by the zipping mechanism, the delivery volume and flow rate in such devices can easily be customized by tailoring the dimensions of the fluid chambers to suit the specific application.

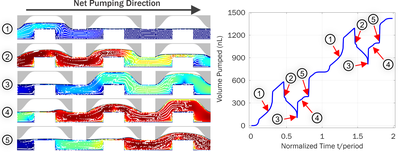

We model the peristaltic zipping micropump concept with COMSOL Multiphysics® by coupling electrostatics (AC/DC Module), solid mechanics (Structural Mechanics Module), and hydrodynamics (Microfluidics Module) interfaces within 2D and 2D axisymmetric simulation domains. A moving mesh with hyperelastic smoothing captures the deformation of the fluid domain imposed by the motion of the electrostatically actuated diaphragm, while a Global ODEs and DAEs interface solves for the volumetric displacement over time. The Particle Tracing for Fluid Flow physics interface is then utilized ex post facto to aid in visualizing the resulting fluid transport throughout the device. Using our model, we investigate the throughput of the micropump for various geometries and actuation sequences of the three chambers, and we demonstrate achievable flow rates ranging from pL/s – μL/s for actuation voltages of ~100 V. The numerical model and results presented herein constitute an important first step toward understanding the coupled fluid-solid interactions within microfluidics-based electrostatic zipping actuators, and reinforce the notion that this mechanism poses an intriguing framework for the future development of novel micropumps and other innovative MEMS devices.