Effect of Geometry of the Grooves on the Mixing of Fluids in Micro Mixer Channel

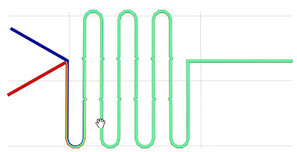

Understanding the flow fields at the micro-scale is a key to develop methods of successfully mixing fluids for micro-scale applications. This paper investigates flow characteristics and mixing of three different geometries in micro-channel. A Circular groove micro mixer has been designed and simulated. One such channel is shown in Figure1. The geometry of the channels taken was rectangular with a dimension of 200µm wide, 200µm deep and 7.7 mm long. In first channel there were circular grooves and in the second channel there was rectangular grooves in the flow fields, while in the third geometry, there were triangular grooves. COMSOL Multiphysics was used to investigate the flow characteristics within these micro fluidic models for three different geometries. A species 2D model was created for three geometries and simulations were run in order to investigate the mixing behavior of two different fluids with viscosity of water (1mPas). Water and acridine orange dye was used to simulate the effect of two different fluids. The results showed that the mixing behavior strongly depended on the channel geometry when other parameters such as fluid inlet velocity, viscosity and pressure of fluids were kept constant. One such mixing behavior is depicted in Figure2. In two geometries lateral pressure and swirling vortexes were developed which provided better mixing results. Creation of swirling vortexes increased diffusion gradients which enhanced diffusive mixing.

下载

- ranjan_presentation.pdf - 0.9MB

- ranjan_paper.pdf - 0.7MB

- ranjan_abstract.pdf - 0.2MB